Understanding Acrylic Board Properties for Optimization

Key Physical and Chemical Characteristics of Acrylic Boards

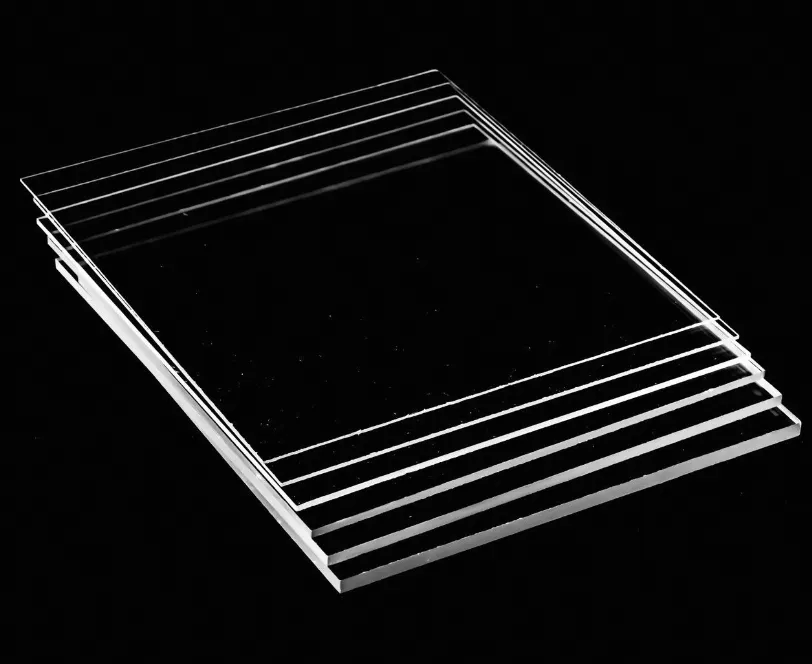

Acrylic boards are highly valued in various industries for their exceptional clarity and transparency. Their light transmittance can reach up to 92%, surpassing that of traditional glass. This makes acrylic boards ideal for applications that require clear display panels, such as retail signage and protective barriers in medical settings. Moreover, one notable property of acrylic boards is their outstanding chemical resistance. They are designed to withstand harsh environmental conditions and resist a variety of chemicals. This resistance ensures they maintain their structural integrity, even when exposed to solvents and acids frequently encountered in industrial and laboratory environments.

In addition to their clarity and chemical resistance, acrylic boards boast being both lightweight and robust. Weighing approximately half as much as glass, they offer significant ease in handling and installation without compromising on strength. This property is beneficial in applications like large-scale glazing projects and portable displays. Thermal stability is another key characteristic of acrylic boards. They can endure temperature variations from -20°C to 80°C without losing their form or becoming brittle, making them suitable for both indoor and outdoor use. These combined properties make acrylic boards an optimal choice for a wide range of applications.

Types of Acrylic Boards and Their Performance Metrics

In my experience, choosing the right type of acrylic board hinges heavily on understanding the available varieties and their performance metrics. Two primary types are extruded and cast acrylic, each offering distinct advantages. Cast acrylic is often lauded for its superior optical clarity and impact resistance compared to extruded acrylic. This makes it the preferred choice for high-quality applications where visual performance and durability are critical, such as in illuminated displays and intricate architectural features.

Performance metrics like tensile strength and impact resistance play a vital role in selecting the appropriate acrylic board type for a project. For instance, cast acrylic boards typically exhibit tensile strengths exceeding 10,000 psi, making them well-suited for structural applications. Meanwhile, specialty acrylics, such as colored or frosted variants, offer aesthetic benefits and vary in their physical properties. Understanding these variations allows for smarter decision-making, especially when specific project requirements need to be met without compromising performance.

Additionally, factors like thermal conductivity and weather resistance are important considerations. Some acrylic boards are specially engineered to provide excellent weathering resistance, mitigating risks like yellowing over time. This attribute ensures that the visual appeal and integrity of the boards are maintained, even when exposed to adverse weather conditions.

Surface Treatment Techniques for Enhanced Durability

Polishing Methods to Reduce Surface Friction

Polishing techniques are crucial for reducing the surface friction of acrylic boards, leading to smoother finishes that are visually appealing for various applications. Mechanical polishing can achieve levels of clarity that enhance display settings, making it ideal for showcases and signage. Using the right polishing agents is essential for improving surface resilience against abrasions. Fine abrasives or special compounds designed specifically for acrylics help maintain the material's aesthetic over time. An additional benefit of effective polishing methods is the increased light transmittance potential; polished acrylic surfaces can reach over 97% clarity, which is highly desirable for lighting solutions.

Anti-Scratch and UV-Resistant Coatings

Implementing anti-scratch coatings significantly extends the life and appearance of acrylic boards by shielding them from daily wear and tear. A relevant study has highlighted that these coatings can reduce the visibility of scratches by up to 75%, thus preserving the material's look and integrity. UV-resistant coatings are vital for outdoor applications as they protect acrylics from discoloration and degradation due to sun exposure. These coatings prevent harmful ultraviolet rays from compromising the acrylic boards, thereby prolonging their lifespan. Together, anti-scratch and UV-resistant coatings not only enhance durability but also offer added safety by minimizing risks of cracking or shattering, which is essential in environments with high pedestrian activity.

Optimizing Cutting and Shaping Processes

Laser Cutting vs. CNC Machining for Precision

Choosing between laser cutting and CNC machining for acrylic boards is crucial for achieving precision and quality in your projects. Laser cutting is widely preferred for its ability to execute intricate designs with remarkable detail without compromising the material integrity. Its precision makes it ideal for high-end applications requiring detailed patterns and clean edges. On the other hand, CNC machining is versatile in handling thicker materials and is beneficial when uniformity and bulk production are necessary. It offers unique shapes and sizes but tends to be slower compared to laser cutting. Both methods require optimization of settings, such as adjusting the power, speed, and frequency for laser cutting, to ensure exceptional cut quality and edge finish.

Minimizing Edge Stress During Fabrication

In the fabrication process of acrylic boards, minimizing edge stress is essential to prevent damage such as cracking or fracturing. Techniques such as using a slow feed rate during cutting can significantly reduce edge damage, resulting in a high-quality finish. Selecting the appropriate tools, particularly blades designed for acrylics, can greatly minimize chipping, leading to smoother edges. After fabrication, post-treatment methods like edge polishing can enhance the structural integrity, ensuring that the finished product maintains its aesthetic appeal and durability. Adopting these strategies not only improves the overall production quality but also ensures the longevity of the acrylic material in various applications.

Temperature and Environmental Factor Management

Thermal Expansion Control Strategies

Thermal expansion can significantly impact the performance of acrylic boards, especially in environments with fluctuating temperatures. To mitigate distortions caused by these fluctuations, implementing expansion joints or techniques to pre-stress acrylic can be effective strategies. Conducting experiments and simulations to anticipate thermal reactions is crucial, as it helps producers and users adjust installation methods accordingly, ensuring better longevity. Engineers often report a reduction in stress fractures through the incorporation of thermal control designs, underscoring the value of pre-planning during the design phase.

Moisture and UV Exposure Mitigation

Managing moisture and UV exposure is critical for maintaining the quality of acrylic boards. Moisture can lead to clouding and degradation; thus, incorporating moisture barriers in applications with fluctuating humidity levels is advisable. Additionally, integrating UV stabilization in acrylic through stabilizers during manufacturing can significantly extend its lifespan, offering protection against sun and water damage. Industry best practices recommend routine inspections for signs of moisture infiltration or UV damage to allow for proactive maintenance. Such measures ensure that acrylic boards retain their optimal functionality throughout their lifecycle.

Maintenance Practices for Long-Term Performance

Cleaning Protocols to Prevent Degradation

Maintaining acrylic boards involves regular cleaning protocols that prevent degradation and prolong their lifespan. Using non-abrasive cleaners specifically designed for acrylic is crucial to avoid scratches and discoloration, which can mar the board's surface and visual appeal. During the cleaning process, the choice of cleaning tools is equally important; utilizing soft or microfiber cloths ensures gentle treatment of the surface without inflicting any damage. Moreover, setting up a scheduled cleaning routine allows for early identification of any emerging issues, contributing to the board's longevity and consistent appearance. Implementing these protocols not only preserves the physical condition of acrylic products but also enhances their aesthetic value over time.

Structural Integrity Monitoring

Regular monitoring of structural integrity is fundamental in maintaining the performance and safety of acrylic boards. Conducting routine inspections for cracks or signs of wear can immediately address potential problems, preventing them from developing into major issues. Employing tools like ultrasound technology and visual inspections offers a precise assessment of the board's condition, enabling owners to decide when repairs or replacements are necessary. Establishing industry benchmarks for these inspections ensures systems remain operational and visually appealing, thus maintaining high customer satisfaction. By prioritizing ongoing maintenance, businesses can safeguard the structural reliability and aesthetic integrity of their acrylic products.

Sustainable Practices in Acrylic Board Usage

Recycling Methods for Acrylic Waste

Exploring innovative recycling methods, such as chemical recycling, is essential in making strides toward sustainable acrylic use. This approach allows acrylic waste to be transformed back into raw materials, significantly reducing environmental impact. Collaboration with recycling partners can enhance the operational efficiency of these processes, improving recovery rates of acrylic products. By tracking waste across the production lifecycle, companies can innovate in managing resources, which ultimately minimizes the environmental impact. As sustainability becomes a focal point, the efficient recycling of acrylic waste is not just beneficial but necessary for long-term viability.

Energy-Efficient Manufacturing Adjustments

Adopting energy-efficient manufacturing processes is a crucial step for businesses looking to lower costs and minimize environmental footprints. Optimizing machinery and reducing waste are strategies that can lead to a significant decrease in energy use, often yielding a 20-30% reduction, according to industry research. Moreover, investing in renewable energy sources for production facilities can further enhance sustainability. Many industries have reported significant decreases in energy costs by transitioning to renewable sources, exemplifying that these adjustments not only support sustainable practices but also provide economic benefits in the long run.

FAQ

What are the key properties of acrylic boards?

Acrylic boards are valued for their clarity, chemical resistance, lightweight robustness, and thermal stability, which makes them suitable for a wide range of applications.

What are the types of acrylic boards?

The main types of acrylic boards are extruded and cast acrylic, each offering different benefits such as optical clarity and impact resistance.

Why is surface treatment important for acrylic boards?

Surface treatment, like polishing and coatings, enhances durability, reduces friction, and improves the aesthetic and functional qualities of acrylic boards.

How does cutting method affect acrylic board quality?

Choosing between laser cutting and CNC machining impacts the precision and quality of the cutting edges, critical for project specifications.

How can thermal and moisture factors be managed in acrylic boards?

Managing these factors involves using strategies like expansion joints, moisture barriers, and UV stabilizers to maintain board quality and longevity.