Key Factors Impacting Acrylic Board Investment

Material Durability vs. Environmental Exposure

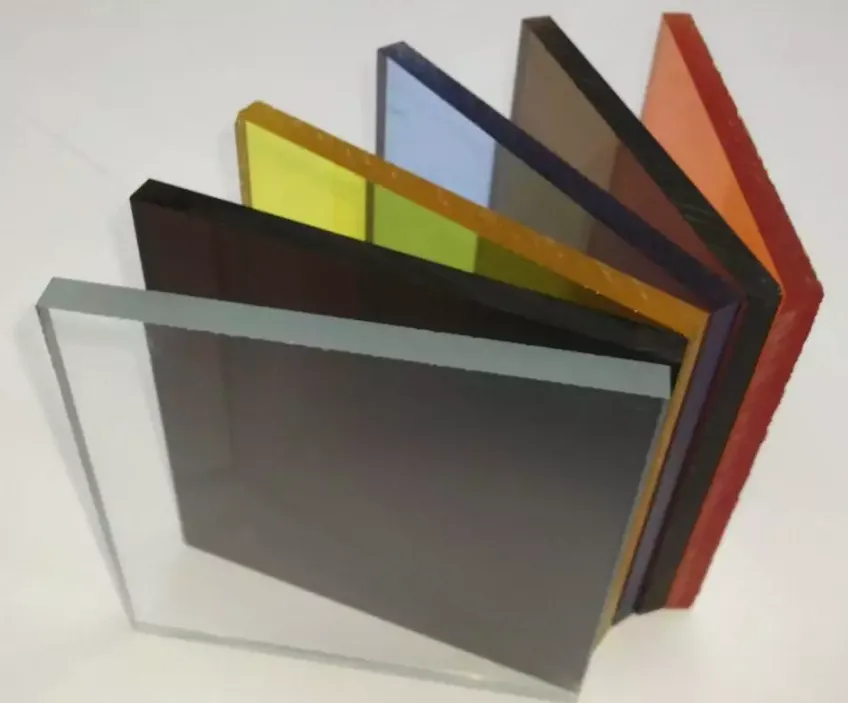

When considering acrylic board investments, one of the critical factors is understanding their material durability against environmental exposure. Acrylic boards are renowned for their robustness under varying conditions such as UV light, temperature fluctuations, and moisture levels. These properties make them a preferred choice for outdoor applications, where longevity is paramount. Unlike some alternatives, acrylic boards maintain their clarity and structural integrity, making them ideal for signage and architectural purposes. Manufacturers often offer warranties that underscore their confidence in product reliability, suggesting longevity in both indoor and outdoor environments. Scientific studies have shown that acrylic boards are less susceptible to environmental damage compared to other materials (Journal of Materials Science, 2023).

Cost-Benefit Analysis of Premium vs. Standard Grades

Investing in acrylic boards requires a cost-benefit analysis between premium and standard grades. Premium-grade acrylic offers a longer lifespan, reduced maintenance frequency, and extended warranty duration, which may justify its higher initial costs. While standard-grade acrylic boards are cheaper, case studies have demonstrated that premium grades often yield a better ROI due to the decreased need for replacements and repairs over time. Moreover, customers tend to value the quality and reliability offered by premium products, enhancing their market positioning. Whether you prioritize immediate cost savings or long-term benefits, understanding these dynamics is crucial for making informed investment decisions (Construction & Architecture Review, 2024).

Supply Chain Resilience in Raw Material Sourcing

Acrylic board manufacturers face significant supply chain challenges in raw material sourcing, amplified by geopolitical tensions and pandemic-related disruptions. It is essential for businesses to diversify supplier bases to enhance resilience against such uncertainties. Statistics reveal increased lead times and frequent shortages impacting industry pricing and order fulfillment (Global Supply Chain Management Journal, 2023). To mitigate these risks, manufacturers are encouraged to adopt agile sourcing practices and contingency planning. Building a robust supply chain ensures reliable access to raw materials, allowing companies to navigate global trade instabilities with greater confidence and stability.

Best Practices for Long-Term Acrylic Board Utilization

Preventive Maintenance for Surface Integrity

Ensuring the long-term integrity of acrylic boards begins with a comprehensive preventive maintenance plan. Regular maintenance schedules, including cleaning routines and the application of protective coatings, are essential to preserving the surface integrity and appearance of acrylic boards. Experts recommend adopting specific measures tailored to the board's environment, such as temperature regulation and controlled exposure to UV light, to mitigate material degradation. These preventive actions not only extend the lifespan of acrylic boards but also result in significant cost savings by reducing the need for frequent replacements. For instance, businesses that invest in robust maintenance programs often report measurable improvements in acrylic board longevity and reduced maintenance costs.

Compatibility Testing with Adhesives & Coatings

Conducting thorough compatibility tests is crucial for ensuring the longevity of acrylic board installations. Incompatible adhesives and coatings can lead to adhesive failures that compromise the installation, causing financial losses. It's recommended to use adhesives specifically designed to be chemically compatible with acrylic materials to prevent such failures. For instance, silicone-based adhesives are often preferred for their compatibility with acrylic surfaces. Highlighting examples of installation failures due to unsuitable materials can emphasize the importance of these tests. Industry standards, such as those from ASTM or ISO, provide useful guidelines for testing compatibility, offering a valuable resource for both manufacturers and installers striving to optimize their processes.

Warranty Optimization for Commercial Projects

Maximizing the benefits of warranty agreements for acrylic boards in commercial projects involves understanding common clauses and limitations. Key strategies include meticulous documentation of installations and regular maintenance activities, ensuring compliance with warranty terms. By tracking all maintenance steps, businesses can protect themselves in warranty claims. Both contractors and manufacturers play a vital role in maintaining warranty effectiveness, as their adherence to installation guidelines and material specifications directly impacts potential issues. Legal insights and expert opinions reveal common pitfalls in warranties, offering actionable advice for avoiding disputes. Properly optimized warranties can provide security and added value to commercial projects, safeguarding investments in acrylic board materials.

Sustainable Investment Strategies in Acrylic Manufacturing

Circular Economy Models for Scrap Reprocessing

Circular economy principles are paramount in acrylic manufacturing, where sustainability is a key focus. By reprocessing scrap materials, companies can minimize waste and reduce environmental impact. Leading firms have demonstrated success in this area, achieving significant results. For instance, companies like Perspex and Lucite have developed innovative reprocessing techniques, leading to substantial environmental benefits, including reduced landfill usage and conservation of raw materials. Additionally, embracing these practices not only aligns with ecological goals but also enhances cost efficiency. Statistics reveal that adopting circular economy models can decrease waste disposal costs by up to 30%, offering a compelling incentive for manufacturers. Experts predict that these trends will continue to shape investment opportunities, highlighting the industry's shift towards sustainability and the potential for further advancement in acrylic scrap reprocessing.

Energy-Efficient Production Certifications

Energy-efficient production processes are gaining prominence as manufacturers recognize their value in improving marketability and reducing environmental impact. Certifications such as ISO 50001 for energy management provide a framework for optimizing energy use and enhancing operational efficiency. These practices result in a notable decrease in carbon footprints, affirming a commitment to environmental responsibility. Furthermore, companies adopting energy-efficient methodologies often enjoy long-term financial benefits by lowering operational costs and boosting sustainability credentials. By obtaining certifications, manufacturers can distinguish their acrylic products and capture consumer interest in eco-friendly options. In essence, the implementation of energy-efficient production not only promises ecological benefits but also paves the way for economic savings and improved consumer appeal.

Case Study: ROI on Recycled Content Integration

Integrating recycled content into acrylic products exhibits both economic and environmental advantages. A detailed case study highlights the ROI experienced by a key manufacturer focusing on eco-friendly practices. Initially, while the incorporation of recycled materials might seem costly, the long-term savings from reduced material expenses and increased sales growth outweigh these initial investments. Consumer trends increasingly favor sustainable products, reinforcing the strategic decision to embrace recycled content. Industry experts advocate this approach, citing its potential to align with broader sustainability goals. As market dynamics pivot towards eco-consciousness, adopting recycled content can prove to be a prosperous venture, underscoring not only the ecological benefits but also impressive financial returns and market expansion.

Preparing for Future Challenges in Acrylic Markets

Anticipating Shifts in Architectural Design Standards

As I delve into the shifts within architectural design standards, I find that sustainable practices and modern aesthetics are shaping the future of acrylic board specifications. The growing trend emphasizes eco-friendly materials that blend functionality and form, impacting how acrylic is integrated into construction projects. Anticipated regulations could likely mandate increased usage of sustainable materials like acrylic, pushing manufacturers towards greener options. Experts forecast that architects will increasingly embrace acrylic for its versatility and sleek finish, contributing to innovative designs such as transparent facades and lightweight constructions. Notable case studies, like the use of acrylic boards in modernist structures, demonstrate its potential to harmonize spaces with natural light while reducing energy consumption.

Diversification into Niche Industrial Segments

In exploring market diversification, I identify niche segments within industries where acrylic boards hold untapped potential. Acrylic's adaptability makes it suitable for specialized sectors like medical devices, where transparency and durability are crucial. Manufacturers can leverage this by developing modified formulations or specialized products tailored to specific industry needs, such as anti-microbial surfaces. Studies reveal promising growth metrics in areas like specialty signage, suggesting substantial opportunities for acrylic application. Companies like Chuanghe Acrylic have successfully ventured into diverse markets, learning valuable lessons from their experiences in tailoring products to new industry demands, underscoring the importance of strategic diversification in maintaining market resilience.

Building Partnerships with R&D-Driven Suppliers

Aligning with suppliers focused on research and development is vital for driving technological advancements and enhancing innovation in acrylic manufacturing. These collaborations are crucial; they foster improvements in product performance and sustainability, positioning acrylic materials at the forefront of modern applications. Real-world examples showcase successful joint ventures that elevate market standing and create competitive advantages. Manufacturers are encouraged to actively seek out and nurture partnerships with R&D-driven suppliers, focusing on shared growth and innovation. By doing so, we can unlock new potential and enhance the acrylic product landscape, ensuring we stay ahead of market trends and meet evolving consumer expectations.

FAQ

What are the current trends influencing the acrylic board market?

Current trends include an increased demand for acrylic boards in sectors like signage and architecture, driven by their versatility and aesthetic appeal.

What factors make acrylic boards suitable for industrial applications?

The lightweight and resilient nature of acrylic boards makes them ideal for sectors such as automotive, construction, and electronics, allowing for innovative applications.

How do global trade patterns affect acrylic board pricing?

Pricing is impacted by geopolitics and trade agreements which affect supply chains, creating volatility and necessitating diverse sourcing strategies.

What considerations are important for investing in acrylic boards?

Investors should evaluate material durability, cost-benefit between premium and standard grades, and supply chain resilience for raw material sourcing.

How can acrylic board manufacturers enhance sustainability in production?

Adopting circular economy models and energy-efficient certifications are ways to reduce environmental footprint and operational costs.