Innovation Meets Performance in Modern Material Solutions

In today’s manufacturing and design industries, material choice can determine the long-term success of a project. Whether in architecture, automotive components, signage, or medical devices, the need for durable, lightweight, and versatile materials has never been more critical. Blow Molded Acrylic Sheets have emerged as a preferred option for many high-impact applications, offering an outstanding combination of mechanical strength, clarity, and workability. These sheets are manufactured using a specialized blow molding process that enhances their resilience and shapes them to fit complex forms with ease. The result is a product that not only meets the physical demands of modern construction and production but also supports aesthetic goals and environmental considerations. Their rise in popularity reflects a broader trend toward innovative materials that balance performance, safety, and cost-efficiency in demanding environments.

Strength and Durability

Exceptional Impact Resistance

Blow Molded Acrylic Sheets are well known for their superior strength compared to conventional plastic materials. The blow molding process enhances molecular alignment within the sheet, resulting in a robust structure capable of withstanding significant physical stress. This makes them ideal for environments where impact or vibration is common, such as in vehicle interiors, industrial machine guards, or outdoor signage exposed to extreme weather conditions. While acrylic in general is already more durable than glass, blow molded versions go even further by offering additional protection without adding excessive weight. In many high-traffic or rugged applications, this level of strength translates into fewer replacements, lower maintenance costs, and improved user safety. The sheets retain their integrity even when subjected to repeated force, making them a smart choice for both protective and structural uses.

Long-Term Wear Resistance

A critical advantage of Blow Molded Acrylic Sheets is their resistance to wear and degradation over time. Unlike some other materials that may crack, warp, or discolor with extended exposure to the elements or continuous use, these acrylic sheets maintain their structural and visual integrity for years. They are particularly resistant to UV radiation, making them well suited for outdoor applications such as advertising panels, skylights, and safety barriers. The surface of blow molded acrylic is less prone to scratching than other types of plastics, which is essential for maintaining clarity and appearance in consumer-facing products. Whether exposed to sunlight, rain, or mechanical contact, the material remains reliable and performs as expected. This durability makes it especially valuable for industries that demand consistency and long life cycles from their components.

Design Flexibility and Appearance

Easily Molded into Complex Shapes

One of the most attractive features of Blow Molded Acrylic Sheets is their design flexibility. The blow molding process allows manufacturers to create sheets that are not only strong but also highly formable. They can be shaped into intricate curves, domes, and other complex geometries without compromising the strength or clarity of the material. This flexibility enables designers to explore new possibilities in aesthetics and functionality, whether they are crafting modern lighting enclosures, transparent vehicle parts, or architectural installations. Blow molded acrylic is particularly useful in applications that require a seamless or aerodynamic design, helping reduce material joints and improve both performance and visual appeal. The adaptability of these sheets simplifies the production of tailored solutions that meet specific dimensional and structural needs.

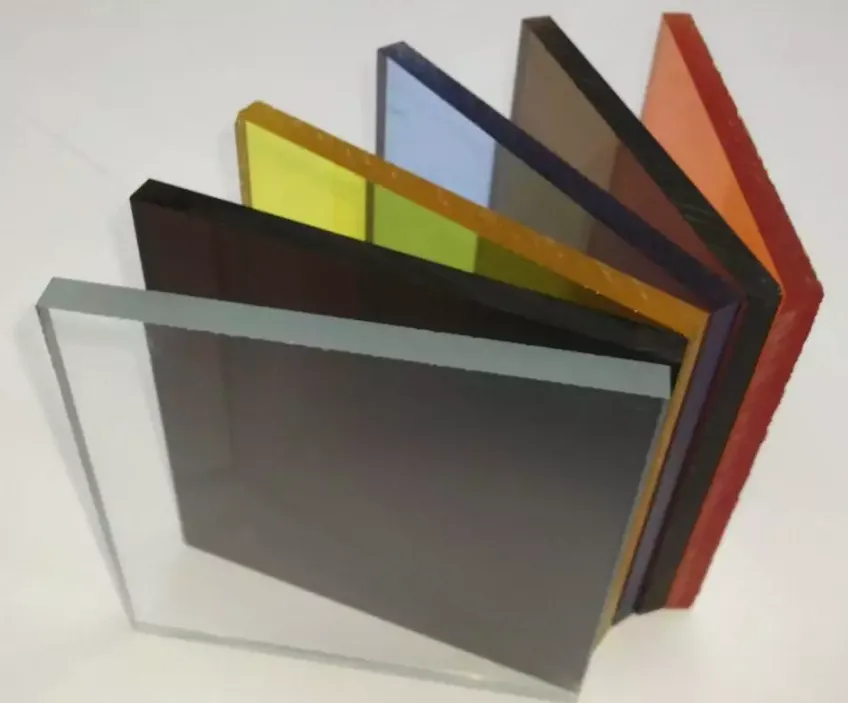

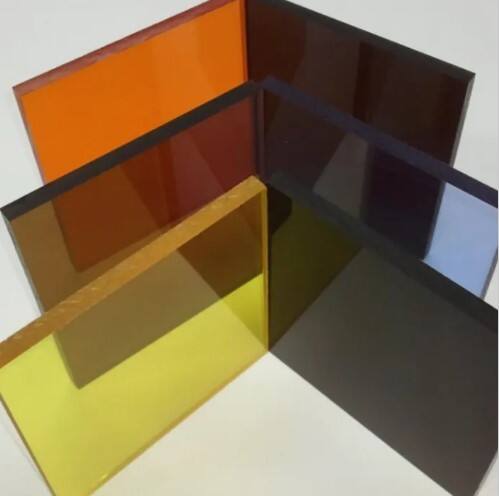

Optical Clarity and Aesthetic Appeal

Blow Molded Acrylic Sheets maintain the exceptional optical clarity that standard acrylic is known for, making them ideal for projects that demand transparency and visual quality. The sheets can be produced in a variety of finishes and colors, from high-gloss clear surfaces to frosted or tinted appearances, offering options that suit various design goals. In environments where visibility is important—such as protective screens, display cases, or lighting covers—this clarity enhances both function and user experience. The surface finish is smooth and professional, often eliminating the need for additional treatments or coatings. With blow molded acrylic, you get a material that’s as visually appealing as it is practical, blending performance with premium design characteristics in one comprehensive package.

Lightweight Efficiency

Reduced Weight Without Compromising Strength

Blow Molded Acrylic Sheets provide an impressive balance between strength and weight, which is a major benefit in industries where both qualities are essential. Compared to glass or other transparent polymers, these sheets are significantly lighter while maintaining or even surpassing impact resistance. This reduction in weight simplifies transportation, installation, and handling during manufacturing processes. For instance, in the automotive or aerospace sectors, reducing weight can improve fuel efficiency and reduce structural strain, contributing to better overall performance and cost savings. Additionally, lighter materials are easier to work with during on-site assembly or fabrication, allowing for faster project completion and reduced labor requirements. In commercial settings where large-scale installations are common, the weight advantage of blow molded acrylic leads to tangible efficiency gains.

Easier Fabrication and Installation

Blow Molded Acrylic Sheets are highly compatible with a wide range of fabrication techniques, including cutting, drilling, routing, and bonding. Their manageable weight and consistent thickness make them ideal for rapid customization without the risk of cracking or distortion. The ease of machining allows manufacturers and installers to achieve precision fits and clean finishes, which is crucial in high-impact or visually sensitive applications. Moreover, the sheets can be joined using adhesives or mechanical fasteners with minimal preparation, streamlining the assembly process across various industries. Whether you're working on a custom signage project, a medical equipment housing, or a structural display case, the user-friendly nature of blow molded acrylic minimizes errors and downtime while supporting high-quality outcomes.

Environmental and Cost Benefits

Energy-Efficient Manufacturing

The production of Blow Molded Acrylic Sheets involves less energy-intensive processes compared to certain alternative materials like polycarbonate or glass. Blow molding allows for efficient use of raw materials and often generates less waste, contributing to lower overall emissions during manufacturing. Many producers also integrate recycled acrylic content into their sheets, supporting a circular economy model that appeals to environmentally conscious consumers and companies. This sustainable manufacturing approach not only reduces costs but also aligns with growing regulatory and market demands for greener industrial practices. By choosing blow molded acrylic, businesses can reduce their carbon footprint without compromising product performance or visual quality, which makes it a forward-thinking option in the age of sustainable innovation.

Long-Term Cost Efficiency

Although Blow Molded Acrylic Sheets may have a higher initial cost than standard plastics, they often provide better value over time due to their extended lifespan and lower maintenance needs. Their durability reduces the frequency of replacements, and their resistance to damage minimizes the need for repairs or downtime in critical applications. Because these sheets require less care to maintain their clarity and structural integrity, they offer operational cost savings in commercial and industrial environments. Additionally, the material’s flexibility and ease of fabrication reduce the need for expensive tools or labor, further lowering total project costs. For businesses that prioritize long-term ROI, blow molded acrylic delivers a compelling blend of upfront quality and future savings.

Versatility in Application

Ideal for Indoor and Outdoor Use

Blow Molded Acrylic Sheets are exceptionally versatile, capable of performing reliably in both indoor and outdoor environments. Their resistance to UV degradation, moisture, and temperature fluctuations makes them ideal for exterior applications such as bus stop shelters, illuminated signage, and greenhouse panels. At the same time, their aesthetic appeal and safe shatter-resistant design make them equally suitable for indoor uses like office partitions, retail displays, and kitchen or bathroom enclosures. This adaptability allows architects, designers, and engineers to specify a single material across multiple aspects of a project, simplifying procurement and ensuring visual consistency throughout. Whether indoors or outdoors, blow molded acrylic rises to the challenge, offering reliable performance without compromise.

Support for Specialized Industries

Many industries have come to rely on Blow Molded Acrylic Sheets for their unique material properties. In healthcare, they are used for cleanroom barriers and medical equipment housings due to their non-porous, easy-to-clean surfaces. In retail, they serve as protective barriers and display components that enhance product visibility while providing durability. In transportation, they are featured in components that require lightweight strength and transparency. This cross-sector utility highlights the material’s capacity to meet diverse regulatory, operational, and aesthetic demands, making it a go-to solution for challenging projects that require high-performance materials in highly specific settings. The ability to serve so many distinct markets is a testament to the engineering and innovation behind blow molded acrylic.

FAQ

What makes Blow Molded Acrylic Sheets different from regular acrylic sheets?

Blow Molded Acrylic Sheets are manufactured using a specialized process that enhances their impact resistance and allows for more complex shapes, unlike regular cast or extruded acrylic sheets which may be more limited in form and strength.

Are Blow Molded Acrylic Sheets suitable for outdoor use?

Yes, they offer excellent UV resistance and weather durability, making them ideal for outdoor applications like signage, bus shelters, and protective panels.

How do Blow Molded Acrylic Sheets compare to glass?

They are much lighter and more impact-resistant than glass while maintaining similar clarity, which makes them a safer and more efficient alternative in many environments.

Can Blow Molded Acrylic Sheets be recycled?

Yes, many manufacturers incorporate recycled content, and the sheets themselves can often be reprocessed, supporting sustainability efforts in commercial production.