Understanding the Material Landscape in Modern Manufacturing

In the world of product design and manufacturing, materials like acrylic and plastic dominate discussions around durability, cost-efficiency, and performance. When comparing Acrylic Versus Plastic, the evaluation extends beyond simple aesthetics. These materials serve different needs in diverse industries ranging from automotive and construction to consumer goods and interior design. Their mechanical strength, transparency, thermal resistance, and weight all play a role in determining where and how each is applied. Companies, engineers, and designers must analyze these factors closely to make informed decisions that align with usage demands, environmental conditions, and customer expectations.

Material Composition and Structural Integrity

What Sets Acrylic Apart in Terms of Physical Strength?

Acrylic, also known as polymethyl methacrylate (PMMA), is renowned for its exceptional clarity and toughness, especially when compared to many traditional plastic types. One of its most notable features is its resistance to shattering, which makes it an excellent replacement for glass in high-impact environments. Acrylic sheets often exhibit higher tensile strength than common plastics, meaning they can withstand pulling forces without breaking or distorting. Additionally, acrylic’s lightweight nature allows it to deliver strength without adding unnecessary bulk, an important consideration in fields like automotive and aerospace design. The rigidity of acrylic means it maintains its shape well under pressure, making it ideal for signage, display cases, and architectural applications that require both visual appeal and strength.

How Does Standard Plastic Hold Up Under Pressure?

Plastic, being a broad term, encompasses various types like polyethylene, polypropylene, and polystyrene, each with different strengths and limitations. In general, plastics are more flexible than acrylic, which can be an advantage or disadvantage depending on the use case. Flexible plastics can absorb shocks better but may warp or deform under long-term stress. While some plastics are highly durable, they often lack the hardness and scratch resistance that acrylic offers. Moreover, plastic can become brittle over time, especially under exposure to UV light or extreme temperatures. This susceptibility to environmental degradation means that not all plastics are suited for outdoor or high-impact applications unless they are specifically engineered with additives or blends for those conditions.

Weather Resistance and UV Protection

Does Acrylic Withstand Outdoor Elements Better?

One of acrylic's standout properties is its resilience against weathering. When discussing Acrylic Versus Plastic, UV resistance is a major factor that favors acrylic. It doesn’t yellow or degrade easily under prolonged sun exposure, maintaining both its structural integrity and visual clarity. This makes acrylic a preferred material for outdoor signs, window glazing, and skylights. Its ability to endure rain, wind, and temperature variations without cracking or fading ensures longevity in harsh environments. In marine applications, for example, acrylic is used for boat windows and instrument panels due to its combination of durability and optical clarity, providing a long-lasting solution even in saltwater conditions.

Can Plastic Handle Environmental Stress?

While some high-performance plastics are engineered to resist UV rays and moisture, many standard plastics fall short in this area. Over time, exposure to sunlight can cause discoloration, brittleness, and material fatigue. Plastics like PVC may require additional treatments or protective coatings to enhance their weather resistance. Moreover, certain plastic types can deform or soften under high heat, making them less suitable for outdoor installations. This inherent vulnerability means that users often have to replace plastic components more frequently when used in exterior applications, increasing long-term costs and maintenance efforts, especially in high-temperature or UV-heavy regions.

Clarity and Aesthetic Longevity

Why Is Acrylic Favored for Transparency?

In applications where visual clarity is crucial, such as aquariums, picture frames, or protective barriers, acrylic’s optical quality stands out. Acrylic offers up to 92% light transmission, rivaling that of glass while being significantly more impact-resistant. Unlike many plastics that may appear cloudy or distort light, acrylic maintains a high level of transparency over time. Furthermore, it resists scratching better than softer plastic materials, ensuring a longer-lasting aesthetic appeal. Its ability to be polished back to its original clarity even after surface damage makes it ideal for use in environments where visual presentation matters, such as retail displays or medical equipment covers.

Are Plastics Visually Suitable for Long-Term Use?

Most generic plastic types lack the optical purity found in acrylic. Over time, plastics are more prone to hazing, scratching, and yellowing, especially in high-exposure environments. This visual degradation not only affects appearance but can also impact function, particularly in applications requiring clear visibility or light diffusion. For example, plastic light covers or protective shields may need to be replaced more frequently due to discoloration or surface wear. While plastics may be initially cheaper and easier to mold into complex shapes, their reduced visual longevity often offsets these advantages when clarity and aesthetics are key performance indicators.

Versatility and Machinability

How Easily Can Acrylic Be Fabricated?

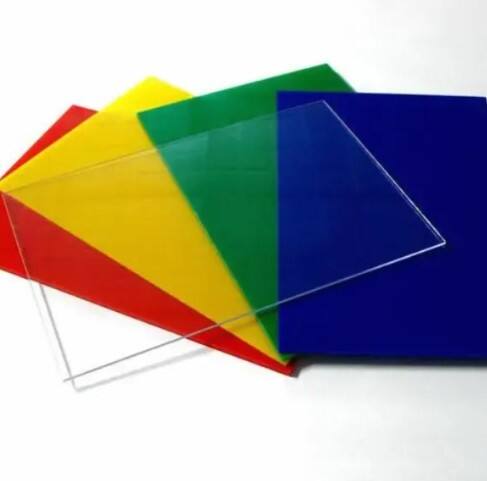

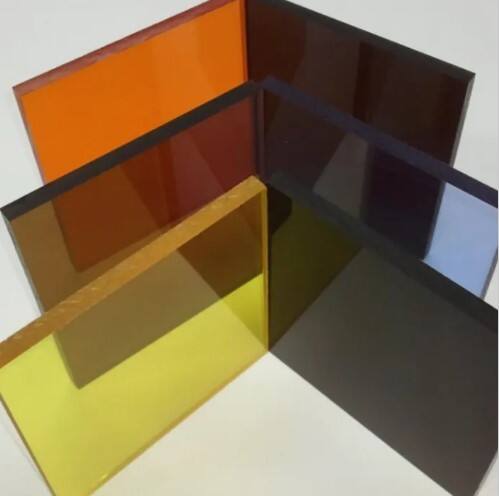

Acrylic offers impressive versatility when it comes to cutting, bending, drilling, and engraving, making it a favorite in industries that demand customization. It can be thermoformed into various shapes without compromising its structural properties, and it bonds well with adhesives or solvents. CNC machining and laser cutting processes produce clean, precise edges on acrylic, which is essential for applications like illuminated signs or point-of-sale displays. Its ease of fabrication, combined with its durability and clarity, allows for creative flexibility across architectural, artistic, and engineering projects. Furthermore, colored and textured acrylics add design diversity without sacrificing performance.

Is Plastic Just as Flexible in Design?

Plastic’s main advantage in terms of machinability lies in its cost-effectiveness and moldability. Injection molding makes it easier and cheaper to mass-produce intricate plastic parts. However, not all plastic types are well-suited to machining or post-processing. Some may melt or warp under heat, making it challenging to achieve precise finishes or maintain dimensional accuracy. In custom projects that require exact fits or high-quality surface finishes, acrylic generally outperforms standard plastic options. Still, for large-scale manufacturing where complexity and speed are priorities, certain engineered plastics may provide a more efficient production workflow depending on the specific project demands.

Cost Versus Long-Term Value

Is Acrylic Worth the Initial Investment?

Though acrylic is generally more expensive than common plastics upfront, its longer lifespan, minimal maintenance, and superior performance often justify the cost. Acrylic products resist impact, UV rays, and weathering, reducing the need for replacements or repairs over time. When calculating total cost of ownership, businesses often find that acrylic provides better ROI in applications requiring clarity, strength, and long-term reliability. Moreover, because it holds its appearance and functionality longer, acrylic also adds value in settings where professional presentation and safety are priorities, such as medical environments, retail stores, or commercial interiors.

Are Plastic Alternatives More Economical?

Plastic options may be more budget-friendly initially, which is a significant factor in high-volume production or disposable item markets. However, the need for regular maintenance, faster wear, and possible environmental degradation can result in higher cumulative costs. For temporary uses or non-critical environments, plastic might serve adequately, but in demanding settings, its shortcomings can lead to increased replacements and potential liability. Depending on the application, choosing plastic over acrylic might make sense for budget-sensitive projects, but it often means compromising on durability, visual appeal, and long-term value.

Environmental Considerations and Recycling

Is Acrylic Environmentally Responsible?

Acrylic is recyclable and has a lower rate of degradation than many plastics, which means its environmental impact can be mitigated when properly managed. Some manufacturers use recycled acrylic in new products, reducing waste and promoting circular production models. However, it is not biodegradable and requires specialized recycling processes. Despite this, its long service life and durability can offset its environmental footprint by reducing replacement frequency and material waste. In industries focusing on sustainability, long-lasting materials like acrylic help minimize resource consumption across the product lifecycle.

How Do Plastics Affect Sustainability Goals?

Plastic pollution is a global concern, and while many plastic types are technically recyclable, the rate of effective recycling is low. Contamination, complexity of sorting, and limited recycling infrastructure lead to a significant portion of plastic waste ending up in landfills or oceans. Certain plastic types contain additives that make them even harder to recycle. While efforts are being made to create biodegradable or compostable plastics, these materials often come with performance trade-offs. For organizations aiming to enhance their environmental responsibility, switching from generic plastic to more sustainable options like acrylic or engineered composites may offer a more responsible path forward.

FAQ

What are the main differences between acrylic and plastic?

Acrylic offers higher clarity, better UV resistance, and greater impact strength, while plastic is often more flexible and affordable, depending on the type.

Which material lasts longer outdoors?

Acrylic generally lasts longer outdoors due to its superior UV resistance and weather durability compared to most standard plastics.

Can both materials be recycled?

Yes, both acrylic and plastic can be recycled, but acrylic usually requires specialized recycling facilities while many plastics suffer from low recycling rates due to contamination.

Is acrylic safer than plastic for display and protective use?

Yes, acrylic is often considered safer due to its shatter resistance and optical clarity, making it ideal for protective barriers and display panels.