Understanding the Need for Visual Clarity

In industries where product presentation, signage, or structural transparency is critical, the clarity of materials can significantly impact effectiveness. Retail displays, protective screens, lighting fixtures, and even furniture all rely on the visual appeal of the materials used. When evaluating options, Acrylic is often compared with traditional plastics due to its sleek appearance, high transparency, and long-term performance. However, the distinction between Acrylic and other plastic materials goes beyond surface impressions. The intrinsic qualities of Acrylic, such as its light transmittance and optical clarity, are essential for industries that prioritize sharp visibility and a premium look. By diving into specific features such as strength, durability, processing ease, and aesthetic appeal, businesses and designers can make informed decisions that support both functionality and brand image. This article unpacks the key differences and advantages, ensuring you get the clearest picture of what sets Acrylic apart.

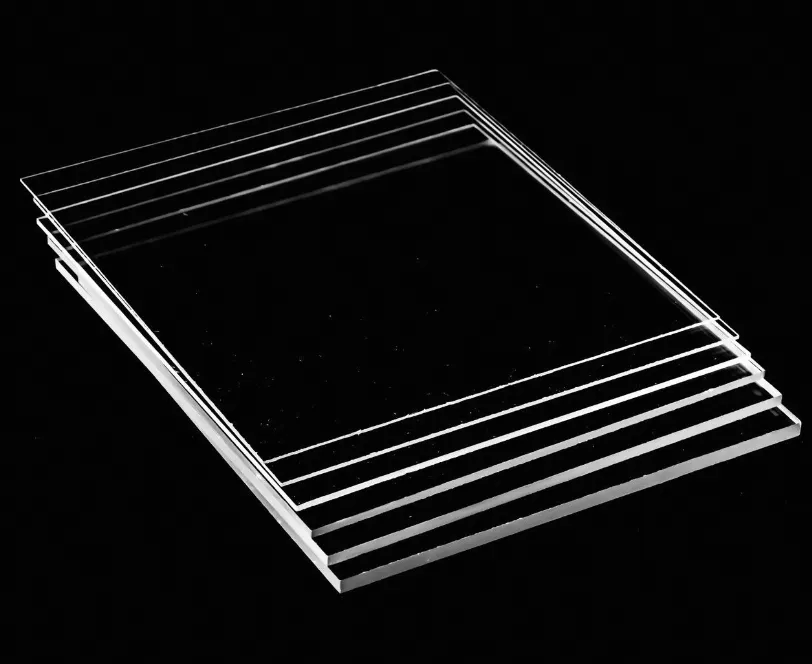

Clarity and Transparency in Material Composition

How Does Acrylic Maintain Superior Clarity Over Time?

Acrylic is widely known for its outstanding optical clarity, transmitting up to 92% of visible light—more than most glass or other clear plastics. This exceptional property results from its highly uniform molecular structure, which allows light to pass through without distortion or fogging. Over time, Acrylic maintains this clarity better than many types of plastic, which tend to yellow, haze, or become brittle with prolonged exposure to sunlight or UV radiation. Even under harsh lighting or continuous display use, Acrylic offers consistent visibility, making it ideal for applications like museum displays, protective barriers, or signage. Its ability to resist aging without sacrificing visual quality makes it a long-term solution that continues to look polished and professional, making it a strong contender in any environment where clear visual impact matters.

What Makes Acrylic a Preferred Choice for High-End Applications?

Designers and architects often favor Acrylic for projects that require both durability and aesthetic precision. Its sleek, glossy surface mimics glass but at a fraction of the weight and with greater resistance to impact. Unlike standard plastic, Acrylic doesn't easily warp, scratch, or lose its shine when properly treated. This makes it perfect for store fixtures, luxury product packaging, and architectural accents where clarity and style must coexist. Additionally, Acrylic is available in a wide range of finishes and thicknesses, offering flexible solutions for both creative and structural applications. Its refined look enhances brand presentation and product display, providing a clear advantage in competitive retail and commercial environments.

Strength and Resistance in Daily Use

Is Acrylic More Impact Resistant Than Regular Plastic?

Although the term “plastic” encompasses a wide range of polymers, many conventional plastic materials like polystyrene or PET tend to crack or deform under stress. Acrylic, on the other hand, is specifically engineered to withstand everyday impact. It is approximately 10 times more impact-resistant than glass and significantly tougher than most general-use plastics. This makes it highly suitable for environments where accidental knocks or pressure may occur, such as in commercial kitchens, offices, or public venues. Its resistance does not compromise its transparency, offering both strength and visibility without trade-offs. For example, in safety shields or sneeze guards, Acrylic stands out as a dependable solution that resists breaking while staying visually pristine.

How Does Acrylic Handle Weather and UV Exposure?

Outdoor exposure can degrade many plastics, leading to yellowing, brittleness, or cracking. Acrylic, however, is specially formulated to resist these effects. UV-stabilized Acrylic retains its clarity and strength even under prolonged sunlight, which is a vital benefit for outdoor signage, garden furniture, and transparent roofing applications. Unlike other plastics that might need regular replacement or maintenance, Acrylic keeps its form and function, reducing long-term costs and improving reliability. This weather resistance also makes it a prime choice for marine applications or poolside structures where light, humidity, and temperature vary frequently. Its resilience ensures visual clarity and surface integrity regardless of climate conditions.

Design Flexibility and Creative Use

Can Acrylic Be Easily Shaped and Modified?

One of the strongest arguments in favor of Acrylic is its processing flexibility. It can be cut, drilled, engraved, bent with heat, or bonded to other materials with relative ease compared to many plastics. This gives designers the freedom to experiment with bold forms, intricate details, and large-scale panels without the risk of shattering or warping. Whether for intricate retail displays or artistic installations, Acrylic supports high customization without sacrificing strength or clarity. Its compatibility with CNC machining and laser cutting tools makes it a staple in fabrication shops, offering faster turnaround and consistent quality in production. Unlike more brittle plastics that limit design potential, Acrylic expands what’s possible in creative manufacturing.

Why Is Acrylic Ideal for Backlit and Illuminated Designs?

In applications where light diffusion or illumination is part of the design, Acrylic outshines its competitors. Its light-transmitting properties make it perfect for backlit signage, LED panels, and architectural lighting. Acrylic sheets can be made in various levels of opacity to create glowing effects without glare or hot spots. Traditional plastic materials often absorb or scatter light unevenly, producing inconsistent results. Acrylic, in contrast, offers smooth diffusion, bringing clarity to light-based designs. Its durability ensures the lighting system remains effective over time without yellowing or surface damage, keeping both function and appearance optimal in the long term.

Maintenance and Long-Term Appearance

Is Acrylic Easier to Clean and Maintain Than Other Plastics?

In both residential and commercial settings, maintenance can play a major role in material selection. Acrylic surfaces are non-porous and resistant to most chemical cleaners, making them easy to wipe down and keep looking fresh. Compared to other plastic types that may absorb stains, degrade under certain cleaning agents, or scratch easily, Acrylic remains user-friendly. With the right cleaning cloth and mild soap, Acrylic can be kept free from smudges, fingerprints, and dust without much effort. Anti-scratch coatings are also available for applications that face high traffic or handling, extending the product’s lifespan while preserving its clean, high-end look.

How Does Acrylic Age in Commercial Use?

Longevity is a crucial consideration for businesses aiming to minimize replacement costs and maintain consistency in visual branding. Over the years, Acrylic has demonstrated outstanding resistance to discoloration, brittleness, and warping. Unlike general-purpose plastics, which can appear dull or discolored after only a few years of use, Acrylic maintains its clarity and structural integrity. Whether used in office partitions, display cases, or menu boards, it provides a reliable and polished surface that holds up to daily wear and tear. This long-lasting quality allows for better budgeting and planning in commercial installations, adding both financial and visual value to any project.

Sustainability and Eco-Friendliness

Is Acrylic More Environmentally Responsible Than Regular Plastics?

As industries and consumers move toward sustainable choices, the environmental impact of materials becomes a vital discussion point. While Acrylic is not biodegradable, it is recyclable and can be repurposed into new products through specialized processing. Many general plastics are either non-recyclable or lack the infrastructure for efficient recovery. In contrast, Acrylic offers a cleaner life cycle, particularly when its durability leads to fewer replacements and lower waste generation over time. Some suppliers even offer recycled Acrylic options, further reducing its footprint. In comparison with disposable or single-use plastic products, long-lasting Acrylic panels help cut down on resource consumption and landfill use.

How Can Acrylic Support Green Building Projects?

LEED certification and green construction principles emphasize the importance of using materials that are low-emission, durable, and low-maintenance. Acrylic contributes positively in all these categories. It does not off-gas toxic fumes under normal conditions and can be manufactured to meet stringent environmental safety standards. Its ability to allow natural light through spaces supports energy efficiency in architectural designs. Furthermore, Acrylic’s longevity reduces the need for frequent replacements or repairs, contributing to the overall sustainability goals of a project. For companies looking to align their facilities with modern environmental standards, Acrylic proves to be a valuable and responsible material choice.

Cost Efficiency and Return on Investment

Does Acrylic Offer Better Long-Term Value?

While the initial cost of Acrylic might be higher than some standard plastics, its long-term benefits often outweigh the price difference. Its durability reduces maintenance and replacement costs, while its premium appearance can enhance the perceived value of products or environments where it is used. Over time, the reduced need for repairs or updates leads to significant savings, especially in commercial or industrial applications where materials are subject to frequent use. This return on investment becomes particularly noticeable in sectors such as retail, hospitality, or medical facilities, where aesthetic appeal and hygiene are equally important. Acrylic proves that spending slightly more upfront can deliver lasting returns.

Can Acrylic Be a Cost-Effective Choice for Custom Projects?

In customized projects, material waste, processing time, and rework costs are significant considerations. Because Acrylic is easy to machine and manipulate, it reduces production time and minimizes errors during fabrication. This efficiency lowers overall project costs, especially when working with complex designs or time-sensitive installations. Additionally, its adaptability means fewer compromises on design intent, helping to meet both creative and financial goals. Compared to more rigid or less forgiving plastics, Acrylic helps streamline production workflows and supports high-end custom solutions at a competitive total cost.

FAQ

What makes Acrylic better than regular plastic for signage?

Acrylic provides higher clarity, better light diffusion, and greater weather resistance than most standard plastics, making it ideal for professional signage applications.

Is Acrylic safe to use indoors and outdoors?

Yes, Acrylic is both UV-resistant and structurally stable, making it safe and reliable for use in both indoor and outdoor environments.

How should Acrylic be cleaned to avoid scratching?

Use a soft microfiber cloth with mild soap and water. Avoid abrasive cleaners or rough sponges to maintain the surface's clarity.

Can Acrylic be recycled after use?

Yes, Acrylic is recyclable through specialized recycling programs that repurpose it into new sheets or products.